The Impact of the Semiconductor Shortage on Lead Times and How to Mitigate It

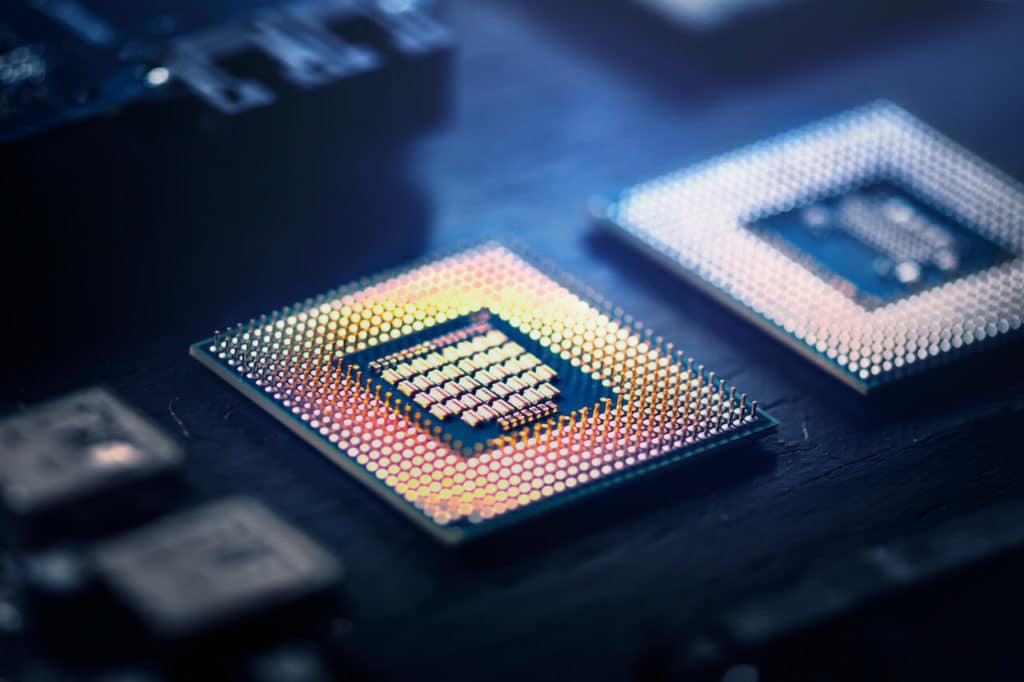

The semiconductor industry is in the middle of a worldwide shortage affecting lead times for production and delivery. This shortage has been caused by several factors, including increased demand from China and the U.S. s well as a decrease in available manufacturing capacity. As a result, many companies need help to obtain the semiconductors they need to run their businesses.

In this article, we will explore the reasons behind the shortage and discuss some of the potential solutions that can help mitigate its effects.

Why Is There a Chip Shortage?

The chip shortage can be described as excess demand and insufficient supply.

This stems from COVID-19 lockdowns in 2020 when the need for technology to support working from home increased, and automakers. Were left competing for semiconductor capacity in Asian factories.

Making matters worse, the COVID-19 Delta variant led to disruptions downstream in South Asia. Exacerbating existing bottlenecks in the supply chain.

Although the COVID-19 pandemic initially created the chip shortage, other factors are also at play. The automotive industry is amid a significant changeover to electric and automated vehicles. Which will require an increased demand for automotive chips – putting pressure on an already stretched industry.

What Does This Mean for Your Business?

If you are currently relying on semiconductors for your operations, the chip shortage has definitely already impacted your business.

Prices and lead times are still trending negatively, with automotive components on allocations and delays in deliveries being common. Although slumping global demand in the consumer electronics sector is becoming more common, it has not shortened lead times or improved availability. For many manufacturers, it is quite the opposite.

According to Everstream’s data, the lead times for some of the chips used in medical devices, industrial systems, telecommunications equipment and cybersecurity software have risen to an average of 52 weeks or more, compared to the previous average of 27 weeks.

Furthermore, the industries that rely most on chips such as automotive, 5G and IoT technology, and smartphones. Which have already taken blows from 2021 and 2022’s uncertainties, are braced for more unknowns.

The last two years have brought a lot of ups and downs for the semiconductor market. According to experts, we can expect these challenges to continue in 2023. Still, one thing is for certain: The supply-demand gap is gradually getting smaller, even if it’s at a very slow pace.

How to Mitigate the Impact of the Semiconductor Shortage

One potential solution to the shortage is using Time Critical logistics services. It allows businesses to expedite the production and delivery of their semiconductors, ensuring that they can maintain a smooth and reliable supply chain even during periods of high demand or limited capacity.

Other possible solutions include investing in alternative sources of supply (e.g., domestic manufacturers or companies with excess manufacturing capacity) and exploring alternate technologies that could replace semiconductors or reduce their reliance on them.

With continued focus and innovation, the impacts of the semiconductor shortage can be mitigated and businesses can continue to thrive in the digital economy.

Why Is Time Critical Logistics Service So Important?

Time Critical logistics service is an essential service for businesses that rely on semiconductors to operate. However, with longer lead times and increased uncertainty in the supply chain, it can be difficult for companies to ensure that they have the materials they need when needed.

According to the study by Bain & Company, several events could cause even more disruption. ”Including the global economy, geopolitical tensions, and shortages of equipment for manufacturing bleeding-edge chips.”

Even before the semiconductor chip shortage, Time Critical delivery was of utmost importance to many companies in the electronics industry. However, with the ongoing shortage, it is more critical than ever for businesses to work with Time Critical logistics providers with the experience and resources needed to ensure the timely and reliable delivery of their shipments.

If you are concerned about how this shortage may affect your business, there are steps that you can take to reduce your reliance on these materials, as well as solutions such as Time Critical services that ensure you have the semiconductors at the right time, at the right place.

Learn more about our Time Critical services that we offered for the semiconductor & electronics industry: royaleinternational.com/services/semiconductor-electronics/