Tier 1 Suppliers: Boosting innovation in the Automotive Supply Chain

Tier 1 Suppliers: Suppliers: Boosting innovation in the Automotive Supply Chain

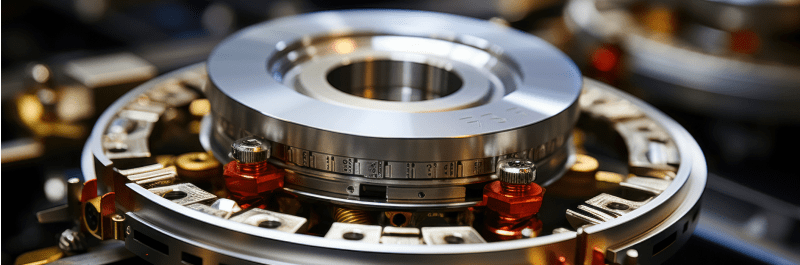

Tier 1 suppliers are companies that directly supply parts or systems to Original Equipment Manufacturers (OEMs). In the context of the automotive industry, these suppliers are responsible for delivering critical components that are essential for the assembly of vehicles. Common examples include brake systems, engines, transmission systems, and electronic modules.

What are the key roles that make Tier 1 Suppliers valuable?

- Quality and Precision: Tier 1 suppliers are known for their high standards of quality and precision. They manufacture parts that must meet stringent specifications to ensure the safety and performance of the final product. For instance, utilizing digitalization and IIoT (Industrial Internet of Things), Bosch enhances process transparency and real-time monitoring to optimize product quality and prevent errors.

- Innovation: These suppliers often drive innovation within the automotive sector. They invest heavily in research and development to create advanced technologies and solutions. According to Bain & Company, Engineering and R&D spending is forecasted to reach 2.7 billion euros in 2026. By investing in cutting-edge research, automotive suppliers can stay ahead of industry trends and meet the evolving demands of consumers and manufacturers alike.

- Efficiency and Reliability: Tier 1 suppliers are critical for maintaining the production timeline and minimising downtime of the supply chain. They must deliver components just-in-time to avoid delays in the manufacturing process. For example, Toyota relies on Denso Corporation to deliver crucial components such as air conditioning systems and engine control units just-in-time for their production lines.

How do Time Critical logistics support Tier 1 Auto Suppliers?

Efficient logistics are fundamental for tier 1 auto suppliers. They must manage the complexities of sourcing raw materials, manufacturing components, and delivering finished products to OEMs. This process involves several key elements:

- Transportation: Extensive transportation networks are essential. Whether it’s shipping raw materials to manufacturing plants or delivering finished components to assembly lines, timely and safe transportation is a top priority.

- Emergency Situations: Unforeseen disruptions, such as natural disasters or production issues, can halt the supply chain. Royale International offers Time Critical solutions that help tier 1 suppliers mitigate these risks by providing rapid response solutions to keep the supply chain moving.

What challenges are faced by Tier 1 Suppliers?

- Global Competition: Tier 1 suppliers face intense competition from companies worldwide. To remain competitive, they must continuously improve their processes, innovate, and provide cost-effective solutions.

With Royale International’s 43 global offices across 23 countries, our experts offer enhanced logistics connections and accommodates complex routing requirements. This global presence ensures that tier 1 suppliers can reliably meet their delivery schedules and maintain a competitive edge in the global market. - Regulatory Compliance: The automotive industry is heavily regulated, with strict standards for safety, emissions, and quality. Tier 1 suppliers must ensure that their products comply with all relevant regulations, which can vary significantly across different markets. Through Royale International’s global offices, we leverage our dedicated account managers who are familiar with local landscapes. They ensure seamless shipments by keeping updated on local customs regulations and compliance check processes. Furthermore, Royale’s logistics solutions are GDP & ISO accredited, which mitigate regulatory risks.

McKinsey reports that suppliers need to manage regulatory changes while also adapting to new technologies such as electrification, which requires significant investment and compliance with emerging standards - Technological Advancements: Keeping up with technological advancements is both an opportunity and a challenge. Suppliers need to invest in new technologies, such as electric and autonomous vehicle components, to stay relevant. According to Car Design News, the transition to EVs and the push for advanced technologies are compressing profit margins for suppliers. This pressure necessitates strategic investments in R&D and innovations while balancing cost reductions across manufacturing and supply chains.

The backbone of the automotive supply chain –

Tier 1 suppliers provide essential components that ensure the functionality and safety of vehicles. Their role in driving innovation, maintaining quality, and managing efficient logistics cannot be overstated. As the automotive industry continues to evolve, the importance of tier 1 suppliers will only grow, making them indispensable partners to OEMs worldwide. Royale International’s Time Critical experts understand the dynamics and challenges of tier 1 suppliers is crucial for offering tailored logistics solutions to the needs of the automotive sector.

_____________________________________________________________

Speak to our Time Critical Experts? : handcarry@royaleinternational.com or nfo@royaleinternational.com.