Digital Twins need Time Critical Solutions

Boeing was one of the first aerospace companies to implement Digital Twins. This led to a 40% improvement in the first-time quality of parts. This ground breaking solution saved them time, money, and a lot of headaches. Adopting digital twin technology marks a significant stride towards innovation for aircraft monitoring and tracking. This approach leverages data to analyse, predict, and improve aircraft maintenance and integrity.

What is a Digital Twin?

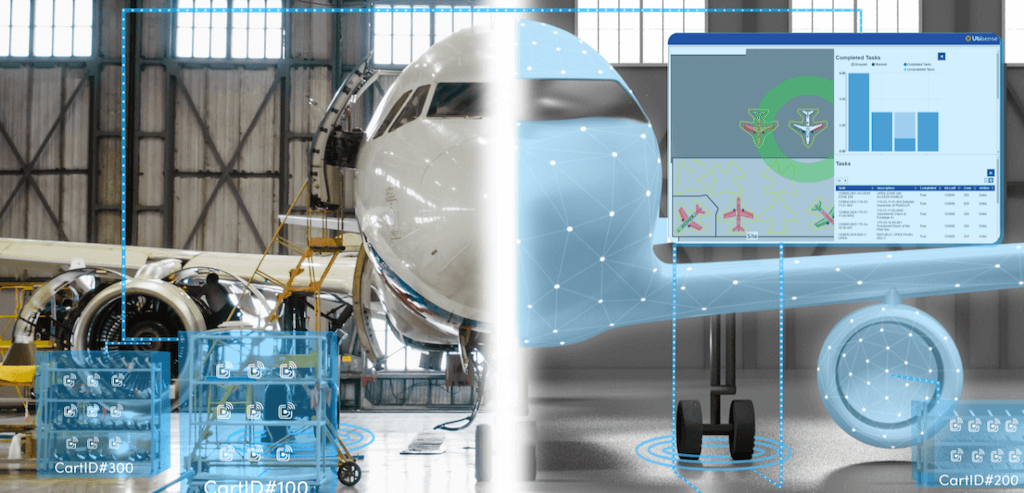

A digital twin in aerospace is a virtual model of an aircraft or component accurately representing its physical counterpart. The physical component has several sensors that relay real-time data on various aspects like energy output, temperature, and overall performance. This continuous flow of data is then applied to the virtual model. As a result, it allows businesses to simulate and analyse performance over time, assess the impact of changes, and explore ways to enhance efficiency. This provides actionable insights into operational practices, offering a platform for experimentation and innovation without impacting actual productivity.

Helping Aerospace Logistics Take Flight

There are many ways in which the aerospace industry can leverage digital twins, it also offers transformative benefits for aerospace logistics, reshaping the way logistics operations are managed and optimised:

#1: Enhanced Route Planning

By accurately modelling transportation networks, digital twins facilitate the optimisation of routes. This leads to more timely delivery schedules and fuel saving, crucial in aerospace logistics.

#2: Improved Supply Chain Visibility and Management

Digital twins enable real-time monitoring and simulation of supply chain activities, providing insights into potential disruptions . This level of visibility aids in making informed decisions and maintaining a smooth logistics flow.

#3. Extending Asset Life Cycles

The use of digital twins in tracking and managing logistics assets — from transport vehicles to cargo — ensures optimal usage, timely maintenance, and reduces the likelihood of unexpected failures.

#4. Supporting Predictive Maintenance

Applying digital twins to predict maintenance needs for logistics infrastructure prevents equipment downtime, ensuring continuous service capabilities. .

#5. Improved Safety and Compliance

Digital twins can simulate logistics operations under various scenarios to identify potential safety hazards and compliance issues, allowing for preemptive action to mitigate risks.

#6: Streamlining Customs Process

By providing detailed and accurate data on cargo, digital twins can expedite customs clearance and ensure adherence to international trade regulations, a vital aspect of global aerospace logistics.

Boarding with a Time Critical Logistics Provider

Digital twins are crucial to maximising efficiency and innovation in the aerospace industry. These advanced technologies enable proactive maintenance and optimised performance. At Royale International, our Time Critical solutions ensure the timely delivery of necessary parts for companies using digital twins for predictive maintenance, helping complete the predictive maintenance process, minimising aircraft downtime, and maintaining operational efficiency.

We employ dedicated account managers who integrate digital twin technology with aerospace logistics operations. These professionals deeply understand the specific demands and time-sensitive nature of coordinating digital twin operations. Their role is key in seamlessly bridging the gap between advanced digital predictions and efficient logistical implementation. Speak to our experts for customised Time Critical solutions.

Need support for your spare part shipments? handcarry@royaleinternational.com or nfo@royaleinternational.com

Learn how we support the Aerospace Industry? Check out this Case Study.