Steel Racks: Shipping 14,000 kilograms

Royale International holds 30 years of experience in shipping automotive parts, like steel racks, valvetrains, ignition systems and various others. The case study below displays Royale’s tailored Time Critical capabilities amidst a congested logistics network.

Background

The automotive industry’s demand will experience a 30-fold increase for autonomous vehicles, despite the 11.3 million production cut in 2021. Manufacturers source their materials, like steel racks and components from all over the globe to keep up with the demand, which altogether causes congested routes for shipment deliveries. Our client needed a rapid Time Critical solution that could avoid a line down situation in their production plant.

Challenge

Our Time Critical experts receives the urgent request in Budapest on Tuesday afternoon. Our client requested the delivery of 32 steel racks (about 14,000 kgs) from Budapest to Ostend. On average, every vehicle uses about 900 kgs of steel. Consequently, the client’s production plant would face delays in its manufacturing of semi-finished products such as the car’s chassis, body, mufflers and exhausts, for the final assembly of their vehicles without the steel racks. Lastly, this would render our client unable to meet their production volume and lead to financial loss.

Solution

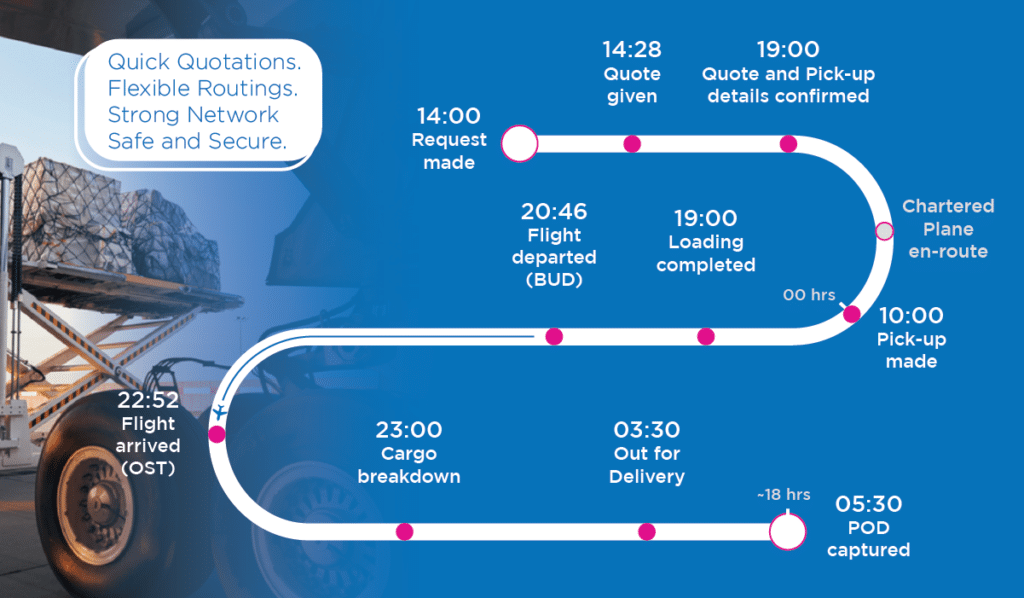

Depsite having difficulties initially to finding a logistics solution with the right capacity for the client, Royale International’s Time Critical experts utilised its longstanding partnerships with airlines and were able to charter a plane. Within 30 minutes, we provided a solution & quotation, and the client gave the go-ahead. The client began preparing the steel racks for Royale’s pick-up upon agreement of the pick-up time. Simultaneously, the chartered aircraft was positioned at Budapest International Airport (BUD), ready for loading. The pick-up of the shipment was on Wednesday morning, and within 19 hours, the steel racks had finally arrived at the client’s plant in Ostend. The client was very satisfied with the early morning shipment as it mitigated line down risk at their production plant and kept operations running.

Want to know six other strategies for all automotive OEMs and Suppliers? Read More

Optimise your logistics process for Autonomous Vehicles? Read More