Lane Risk Assessments Mitigate Risks

There are many supply chain risks in the biopharmaceutical supply chain. According to IQVIA Institute for Human Data Science (as cited by Air Cargo News), the biopharma industry loses US$35 million annually from temperature-controlled failures. Damaged products make up 20% of these failures either by temperature excursion or packaging mishandling. With the digitisation of supply chains, a key process needed to mitigate risks is using a Lane Risk Assessments (LRA). This process can find optimal routes after identifying and evaluating potential risks in the supply chain. Being compliant with international regulations and standards such as the Good Distribution Practice (GDP), ensures quality and integrity of medicinal products.

Royale International’s in-house system is integrated with Validaide, a platform for Lane Risk Assessments. Our Industry Experts ensure that our Life Science logistics solutions use the LRA’s data-driven approach, to identify potential risks and address them with follow-up actions.

Our Data-driven Approach

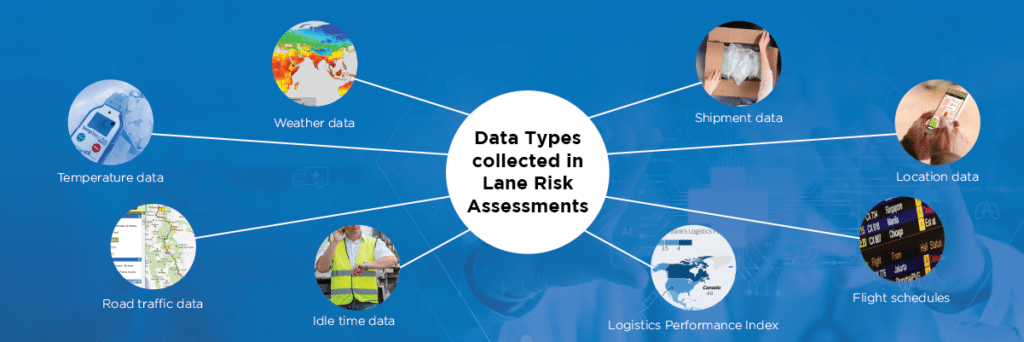

Integrating Validaide into our system gives us access to different data types, which altogether helps our Industry Experts formulate safe and timely solutions for all our clients:

- Temperature data

- Weather Forecasting data

- Shipment data

- Location data

- Road traffic data

- Airline scheduling and performances

Separate consolidation of these data would be lengthy and would need extra steps to ensure they are accurate and reliable. Our integrated system hence, extracts data from external sources and frequently updates our platform for our global teams. Optimal routes forumulated with this data address both time and temperature requirements of the client.

Potential Risks and Follow-up Actions

Biopharmaceutical products face numerous risks when shipped by air freight. Due to non-proper storage conditions or lack of trained staff, high-level risks can come from the loading/unloading of the cargo. Medium-level risk is present during the Regulatory Inspection point at the destination’s airport, if held under non-proper storage conditions. These risks can cause temperature excursions, damage to packaging (and products) and delays. Here are several actions to mitigate the risks:

Using Qualified Life Science Vendors

Choosing airlines that can offer biopharma services, ensures that the staff handling the shipments will be well-trained and follow quality compliant guidelines. Example airlines that offer such services include, Lufthansa, Delta, Cathay Pacific and Emirates. Choosing the right airline also considers which route is optimal according to the time and temperature requirement of the client.

Confirming Validated Equipment and Packaging

Logistics providers need to confirm the temperature storage facilities that are available at the destination or connection points in advance. Through generic LRA, Royale’s Industry Experts can reach out and confirm the type of temperature-controlled facilities available, which can also support the decision on the type of thermal packaging solution used for the shipment. Our experts confirm how much dry ice is required at the origin and whether shipments need re-icing at the destination.

Obtaining Advanced Approval

With the range of biopharmaceutical products, it will be difficult if the logistics provider is not familiar with the local customs. Our Industry Experts work to receive advanced approval from the destination port with our “OKAY TO SEND” procedure. This consequently streamlines documentation, storage booking and delays by customs. The request to avoid the consolidation of shipments especially ensures our shipments do not disrupt the timeline of other products.

Value for the Biopharma Supply Chain

By harnessing Validaide’s system, Royale offers several added values to its customers:

Enhanced Security and Risk Mitigation

The Validaide system firstly enables Royale to identify potential risks along transportation routes, allowing to proactively implement security measures. By minimizing the likelihood of theft, damage, or other security breaches, customers can have peace of mind. Valuable pharmaceutical products are protected throughout the journey.

Regulatory Compliance

Pharmaceutical logistics necessitates overall adherence to stringent regulatory standards. With Validaide, Royale can ensure compliance with relevant regulations and guidelines governing the transportation of pharmaceutical products. By maintaining compliance, customers can avoid costly penalties, delays, and reputational damage.

Optimal Route Planning

Validaide’s data-driven approach empowers Royale to identify the most efficient and reliable routes for transporting pharmaceutical products. By considering factors such as road conditions, traffic congestion, and regional risks, the company can optimize logistics operations, resulting in reduced transit times and improved delivery performance.

Transparency and Accountability

The Validaide system provides a transparent and auditable record of the entire transportation process. This allows Royale to initially provide customers with detailed reports and real-time tracking updates, fostering transparency and accountability. Concurrently, customers can monitor their shipments, track progress, and make informed business decisions based on accurate and timely information.

Continuous Improvement

With access to comprehensive data and insights, Royale can continually evaluate and refine their transportation processes. The Validaide system’s feedback loop enables them to identify areas for improvement, implement corrective actions, and enhance overall service quality.

The use of generic Lane Risk Assessments (LRA) thus benefits the client and logistics provider by formulating data-driven and actionable solutions to avoid temperature-controlled supply chain risks. Royale International’s 30 years of expertise reflects our understanding of the needs of various clients concerning biopharmaceutical products. Finally, our accredited Global Quality Management System (QMS) and generic LRA supports our Industry Experts in their commitment to quality, safety and efficacy under all our solutions.

Know more about our integrated system? Speak to our Industry Experts.

Enquiries about our Global Quality Assurance? Reach Gil Uliel, Global Quality Assurance Manager – Life Sciences on LinkedIn or email at Gil.Uliel@royaleinternational.com