Shipping Life Sciences products in CRT (controlled room temperature)

When it comes to shipping pharmaceutical drugs, blood samples or medical devices, expertise and experience are a prerequisite. A common temperature range in temperature-controlled shipping is shipping in controlled room temperature (CRT). If CRT is not properly maintained throughout storage & transport, this could be detrimental to the product quality. For that reason, it is key to take the following steps to prevent temperature spikes & dips throughout the logistics process.

What is Controlled Room Temperature?

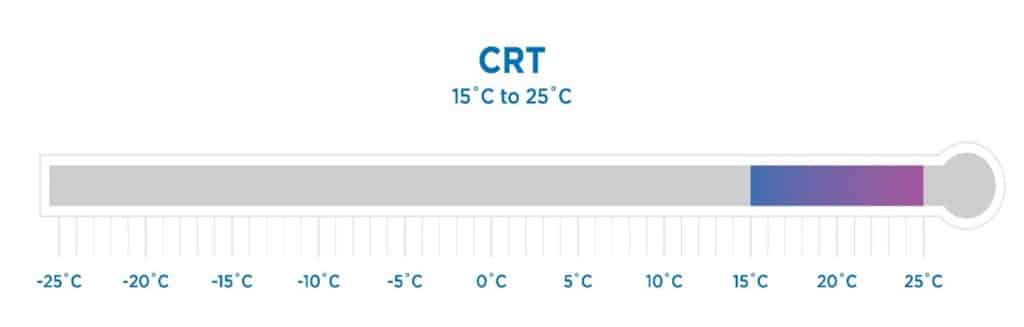

Controlled room temperature (CRT) is an indicated temperature range of +15°C till +25°C Celsius. Occasionally and generally not that case, pharmacies & hospitals allow for excursions within the realm of +15°C till +30°C. To fulfil the controlled room temperature requirements with minimal fluctuations, storage facilities such as cabinets and humidity sensors are specifically designed for temperature stability and product integrity.

To have a more in-depth look at controlled room temperature, please click into the U.S Pharmacopeia (USP) guidelines!

Which products have to be kept under controlled room temperature?

The following paragraph outlines three main product categories that have to be kept within controlled room temperature:

- A variety of pharmaceutical drugs such as opioids, stimulants, atorvastatin, levothyroxine, metformin, lisinopril, amlodipine, metoprolol, omeprazole, etc.

- Four classes of medical devices:

Risk Class I: Absorbent pads, bandages, blood pressure monitors, cervical collars, compression hosiery, conductive gels, examination lights, gait analysers, hospital beds, leather components of orthopaedic appliances, stretchers, surgical microscopes, etc.

Risk Class II: Anaesthesia breathing circuits, blood transfusion tubes, contact lenses, cryosurgery equipment, dental aspirator tips, electronic thermometers, etc.

Risk Class III: Anaesthesia machines, cardiac output units, blood warmers, bone cement, diagnostic X-ray equipment, external defibrillators, electrosurgical units, infusion pumps, lung ventilators, lithotripters, etc.

Risk Class IV: Absorbable sutures, aneurysm systems, antibiotic bone cement, arterial blood sampling kits, cardiovascular stents, cerebrospinal drains, cannulas, prosthetic vessels, vascular anastomosis couplers, etc. - Medical samples such as blood and Covid.

How does Royale maintain USP controlled room compliance?

Royale recognises the importance of climate control for all CRT products. Therefore, we are implementing a focused CRT strategy to uphold the United States Pharmacopeia’s quality standards. Below are the implementations that we proceed to meet the requirements:

- Global dedicated SOPs for the Life Sciences segment

- High-end qualified packaging solutions

- Regular internal audits

- Trained & qualified personnel

- Complaints, deviations & CAPA management

- Global quality management system

How does Royale ensure products are kept within controlled room temperature?

When it comes to CRT shipping, the handling & transport procedures are of critical importance. To overcome temperature-controlled shipping challenges, Royale International has developed a dedicated Life Sciences division that specialises in the worldwide handling and transport of CRT shipments, ensuring products are safely delivered to its destination.

Ranging from customs clearance to import / export permits and product verification reports, all documents that we process fulfil the requirements of the Customs Authority, International Air Transport Association (IATA), and Good Distribution Practice (GDP).

Before shipping CRT products, you can also have a look at this guide to understand the four main factors to consider for your Life Sciences shipments.

Click here to learn more about our Life Sciences services