Temperature-controlled Shipments: Phase Changing Materials VS Water-based Coolants

Transporting temperature-controlled products can be challenging as these products are required to be maintained at a specific temperature range. To provide the right temperature for Life Sciences shipments, third-party logistics providers (3PLs) frequently use energy storage materials in thermal packaging; such as Phase-Changing Materials (PCMs) and Water-based Coolants. The following overview will demonstrate how these two products work and we’ll compare their functionality.

Phase-Changing Materials (PCMs)

Phase-Changing Materials (PCMs), the passive thermal energy storage materials, are widely used as a reliable source of energy to maintain required temperatures in the Life Sciences industry. They are used in combination with water‐based refrigerants (or by themselves) within insulated shipping containers. To increase the duration of thermal control within a given temperature range, PCMs are usually chosen such that their phase change temperature is within the required temperature range of the product being shipped (e.g. 5°C PCM is used to meet a 2 to 8°C temperature requirement). When PCMs change their phase, they effectively prolong the duration of temperature control by cooling the product via its latent heat.

In terms of the advantages, PCMs are highly consistent, cost-effective and environmentally-friendly. PCMs are ideal for temperature-controlled shipments as they give high consistency in performance over a substantial number of time periods and external environments. They provide constant temperatures during the release and absorption of energy. PCMs are also cost-effective as they have low dimensional weight, causing lower shipping costs. Furthermore, PCMs are environmentally-friendly as they are made of biodegradable materials. These materials are non-toxic and non-corrosive, which can easily decompose in the landfill or water. Last but not least, PCMs offer more temperature ranges, and their transport solutions are suitable for a variety of Life Sciences products, ranging from blood samples to stem cells, clinical trials, antibodies, proteins, or other pharmaceutical products.

However, PCMs could have high investment costs in terms of both the equipment and pre-conditioning process. The forwarders of PCMs have to fully understand the shipment requests, ensuring their packaging will perform as required and maintain the highest level of quality.

Click here to learn how we place the PCMs in thermal packaging.

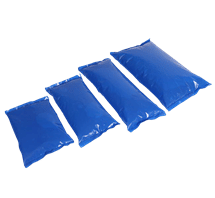

Water-Based Coolants

Water-based Coolants are another form of thermal energy storage unit to maintain required temperatures. They are water-based and cased with thermoplastic materials. Compared to Phase-Changing Materials (PCMs), they are easy to pack and relatively cost-effective in terms of coolants. Furthermore, they are durable with the leak-proof plastic design, and easy to handle with no special handling safety guidelines.

Despite these factors, Water-based Coolants have less temperature accuracy throughout the transport of the journey. They are not as consistent as they supposed to be due to their limited capabilities. As a result, this might not be a good option for some temperature-controlled shipments.

Comparison Table: Should You Use Phase-Changing Materials or Water-based Coolants for Your Life Sciences Shipment?

| Phase-Changing Materials (PCMs) | Water-based Coolants | |

| Characteristics | PCMs are used in combination with water‐based refrigerants (or by themselves) within insulated shipping containers. | Water-based Coolants are water-based and cased with thermoplastic materials to maintain required temperatures. |

| Advantages | – High consistency in performance. – Lower dimensional weight. – Low shipping costs. – Environmentally-friendly. – Offer more temperature ranges. – PCMs are suitable for a variety of Life Sciences products. | – Cost-effective in terms of coolants. – Easy to pack. – Easy to handle. |

| Disadvantages | High investment costs. | Less temperature accuracy throughout the transport of the journey. |

Overall, Phase-Changing Materials (PCMs) are the ideal thermal energy storage units for temperature-controlled shipments/ cold chain transportation.

Royale International is a well-reputed organization that specializes in the worldwide handling and transportation of on-time and sensitive temperature-controlled products for the Healthcare and Pharmaceutical industries. We offer the finest quality of energy storage materials – PCMs to ensure your shipment is maintained at the right temperature. Our Life Sciences logistics procedures are all in compliance with Good Distribution Practice (GDP) regulations worldwide.

To learn more about our Life Sciences services please click here: